Technical Performance

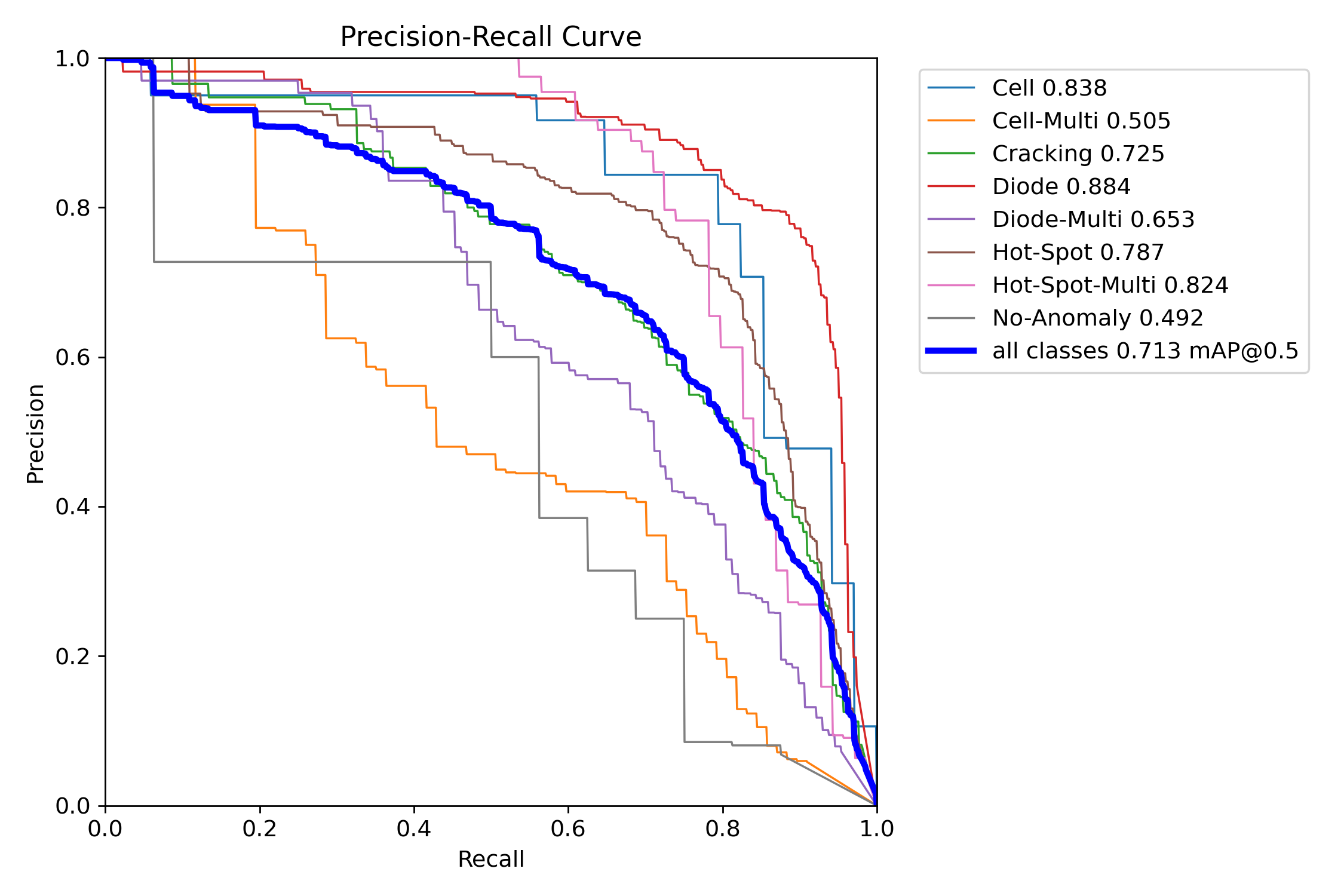

Precision-Recall Curve

Shows the trade-off between precision and recall. High area under the curve (0.713 mAP@0.5) indicates the model effectively minimizes false positives while maintaining detection capability.

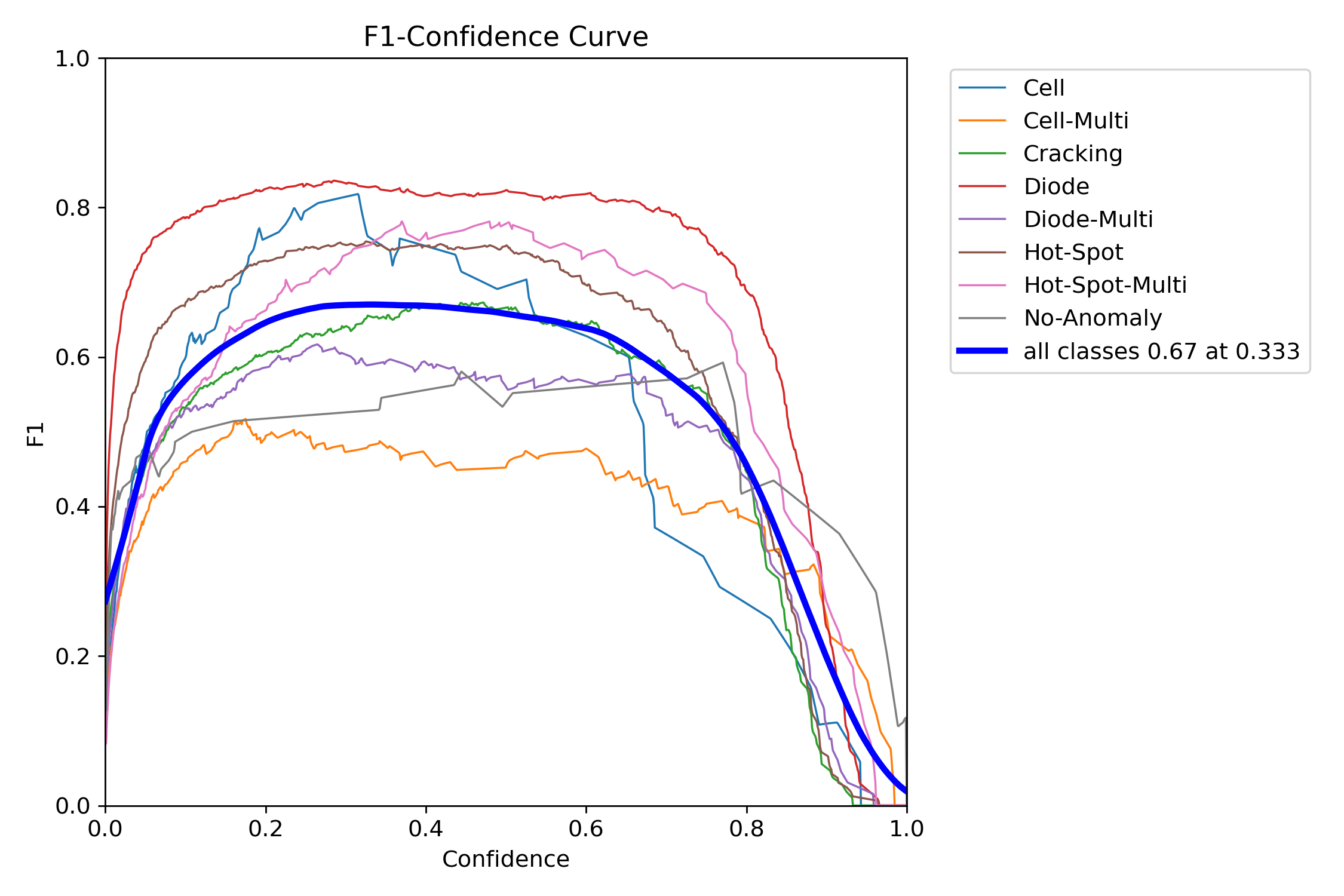

F1-Confidence Curve

The optimal F1 score is achieved at a confidence threshold of approx 0.333. This informs our deployment strategy to balance missed detections against false alarms.

Class-Specific Reliability

Strong Performance: Diode (0.88), Cell (0.83), Hot-Spot (0.79).

Review Needed: No-Anomaly (0.49) - Model is conservative/paranoid (safer for inspections).